OVERVIEW[]

PEO (polyethylene oxide) is a long-chain polymer that can turn water and detergent into excellent bubble juice. It is very popular ingredient and is perhaps the most efficient polymer used by bubbleologists. It is especially loved by giant bubble makers -- many of whom consider it their favorite polymer. It is the active ingredient in J-Lube and PolyOx WSR-301. These popular PEO sources are potent in extremely small quantities. 0.125 grams of fresh PolyOx WSR301 powder is more than enough to make one gallon of bubble juice (that is 0.008 grams per liter water). It can be used as the sole additive or in combination with other polymers.

PEO generally comes in the form of a white, odorless powder. It forms a suspension when combined with water and tends to clump if added directly to water. A number of simple techniques make it simple to mix it with water. Learn about mixing polymers in the article: Polymers - Mixing.

PEO has remarkable characteristics. In the right quantities, it makes closing bubbles trivially easy and makes it easy to blow many bubbles from a single dip of a wand. It provides a property called self-healing which allows a bubble to split rather than break under stress and allows easy bubble-in-bubble creation. It also provides a quality sometimes called elasticity -- a sort of suppleness that allows the bubble film to stretch easily. A small amount of PEO can turn a mix of dishwashing liquid and water into a giant bubble-making powerhouse. It is also suitable for making bubble juice for small bubbles and bubble sculpture.

Not all PEO is the same. Only some versions are suitable for making bubbles. For making bubbles, relatively high molecular weight versions are preferred. The most popular versions of PEO for use in bubble juice are PolyOx WSR-301 and J-Lube (which is a mix of PEO and sucrose which acts as a dispersant). PolyOx WSR-301 has molecular weight of approximately 4,000,000. J-Lube's molecular weight is not published. A chemist at the manufacturer indicates that it has a molecular weight higher than 2,000,000 but would not be more specific.

Molecular Weight. As with all polymers, the PEO molecule is a chain of identical or near-identical units called monomers. The length of the PEO polymer chain determines its properties and usefulness. The chain length is usually communicated as molecular weight (the mass of the atoms that make up a single polymer chain). Low molecular weight PEO is either ineffective or not very effective as a primary bubble juice polymer.

PEO/PEG Distinction. PEO and PEG molecules have the same molecular formula. Some people use the names interchangeably. However, PEG, by convention, refers to low molecular versions and PEO is reserved for high molecular weight molecules. As a result PEG is not generally considered useful for bubble juice. The relationship between molecular weight and viscosity is not a linear one. And properties such as "stringiness" or self-healingness may be tied to a particular molecular weight or even a particular version of the molecule. Even among the molecules called PEO, not all are equally suitable for bubble juice. See Polymers#Polymers_and_Molecular_Weight

OLD VERSION (March 2015): The old version of this page can be found at: PEO RetiredMarch2015. It has some useful information that will be migrated to current version page.

IMPACT ON BUBBLE JUICE[]

PEO can make a solution very self-healing even in minuscule small doses. It makes it easy to blow bubbles-in-bubbles, and bubbles easily split into smaller bubbles under wind-stress. It can make the bubble skins so supple that they split rather than break when under stress and allows bubbles to be distorted quite a bit away from their natural spherical shape without breaking.

The high molecular weight PEO that is usually used in bubble juice has a strong influence even while changing the viscosity only slightly compared to other polymers that have a much bigger affect on viscosity in their useful usage range. It is so powerful that at concentrations enough to significantly influence the viscosity of a detergent and water solution, there is usually too much PEO to be useful. High molecular weight PEO tends to make solutions stringy-mucousy in a way that is hard to describe without having experienced it.

A small bit of PEO can dramatically increase the number of bubbles-per-dip that can be achieved (a property we call bubble-friendliness). This change also more-or-less corresponds to changes in self-healingness associated with PEO. If there is too much PEO, the soap film will often break prematurely making it nearly impossible to blow even a single bubble. When using a tri-string wand, the symptom of too much PEO is often that the film will break (even in calm conditions) before the wand is fully open.

Even just a few drops of a 1% PolyOx WSR301 solution added to a cup of a soap and water solution can increase the bubbles-per-dip from 1 or 2 to well over 50.

SHELF-LIFE AND DEGRADATION[]

High-molecular weight PEO (such as WSR301 and J-Lube) is known to degrade over time even at room temperature into lower molecular weight PEO. It is likely that this is oxidative degradation. Storing PEO in the freezer nearly eliminates the degradation.

Calibrating PEO. Since your PEO's potency may change over time (and may have already changed by the time it reaches you), we highly recommend that you determine your PEO's potency when you receive it and periodically check it to determine if its potency has significantly changed. One method of estimating its potency is discussed in PEO Calibration. But you can use whatever methods. The main idea is to find a fairly objective measure of the PEO's potency and to periodically check it. You could, for instance, measure the viscosity of a 1% or 2% PEO solution. (See Syringe Test for an easy viscosity test.)

Degraded PEO is not necessarily bad PEO. Despite the sound of it, "degraded" PEO is not necessarily to be avoided. Degradation influences how much you needed to use. Many people actually prefer degraded WSR301 and J-Lube because the degraded PEO results in a much less stringy solution at the same performance level. Full-potency J-Lube and WSR301, are so potent that tiny measurement discrepancies can lead to large differences in performance. It is not uncommon for them to stabilize at about 1/4 full-potency. This can happen over a period of as little as six months or may take years depending on storage conditions. Update 2021: Researchers at Emory University have found that degraded high molecular weight PEO is even more effective than undegraded PEO. They suspect that the mixture of polymer lengths that results from degradation is beneficial. FUN FACT! The scientists have mentioned the Soapbuble Wiki as one of their information souces.

Even newly purchased PEO may be degraded!!!! It is important to realize that even if you just purchased a bottle of J-Lube or WSR301 that it may have degraded while sitting in the distributor's warehouse. In the usage section, see general guidelines for determining your PEO's potency at PEO Calibration

As Dow notes in "PolyOx Water-Soluble Resins": "POLYOX Water-Soluble Resins will degrade to lower molecular weights with time and elevated temperature. Higher molecular weight grades are more sensitive than lower molecular weight grades. Samples past their expiration date should be evaluated to confirm that they are within specification limits. Samples that are out of specification should be discarded."

J-Lube and degradation. While there has been speculation on SBF, the Soap Bubble Fanciers Yahoo Group (RIP) that J-Lube is particularly resistant to degradation, January 2015 conversations with the the inventor of J-Lube indicated that it is subject to the same storage issues as PolyOx and was not, contrary to speculation on SBF, engineered to be resistant to oxidation. He recommended storing J-Lube in the freezer to maximize its shelf-life. These conversations also suggested that atmospheric moisture could contribute to degradation.

Calibrate your PEO! We can't emphasize enough the importance of getting a sense of your PEO's potency. Many people report (and we have experienced this ourselves) that their PEO's potency was shifting over time without their realizing it until they had to purchase a new supply -- at which point they had to do a lot of trial-and-error to get their juice working like it used to. See PEO Calibration for a proposed method of gauging your PEO's potency.

Further stability notes. In a comment on another page, Davekni writes:

- Just found an old (1983) paper on PEO solution "degradation" over a two-month interval:

- It indicates that PEO disolved in water forms aggregates of multiple PEO molecules that behave as higher net molecular weight entities. The "degradation" observed appears to be these aggregates hydrating into individual PEO molecules, not breaking any individual molecules. It also shows that 10% isopropyl alcohol inhibits this initial aggregation, and therefore any subsequent "degredation". That likely explains my experience with alcohol slurry liquid, especially since I used more alcohol than typical slurry recepies and made a lower-PEO concentrate (0.1%).

- It also suggests that PEO hydration has an upper time limit where PEO remains aggregated. The aggregated PEO has higher effective molecular weight, so is more effective. As the molecules slowly separate (which occurs even w/o alcohol over a couple months), the PEO viscosity drops.

- I haven't found any similar mention of PAM forming such aggregates, which may explain its apparent increased stability.

- This is all related to stability after disolving. It doesn't apply to anything about storage life of the dry powders.

Potency[]

On this page and elsewhere on the wiki, we refer to PEO potency. What we call potency is gauged by how much the amount of PEO needs to adjusted to get results similar to freshly manufactured PEO. When we say that a batch of WSR301 is at 25% potency, we mean that it is one-quarter (1/4) as potent as when it was manufactured. So, four times as much of it is needed to match the performance of freshly manufactured WSR301.

It should be noted that some characteristics change with potency and aren't restored by simply changing the amount used. For instance, degraded PEO seems to result in juice that is less stringy than when made with fresh PEO even when you adjust for the loss of potency. For this reason, many people actually prefer degraded PEO!

J-LUBE And PolyOx WSR301[]

J-Lube (from Jorgensen Labs) and PolyOx WSR-301 (from Dow Chemical) are the two most popular versions of PEO used by homebrew bubbleologists. Their popularity owes to their effectiveness and availability. Recipes found here and elsewhere indicate a very wide range of amounts used. This range owes to both the fairly wide range over which it is effective and recipes being based on PEO in various states of degradation. Some recipes on the wiki were created before the degradation issue was well-known. So, they may contain amounts of PEO that will overdose bubble juice if full-potency PEO is used.

PolyOx WSR-301 has a molecular weight (MW) of 4,000,000. The PolyOx line has many other product numbers. When ordering PolyOx, it is a good idea to confirm that it is version WSR-301. Some other versions MAY be appropriate also. There is a totally unrelated product called Polyox from Bimeda that is not PEO at all. Be sure that you are purchasing the right product!

J-Lube's molecular weight is not a matter of public record but a chemist at Jorgensen has said that it is at least 2,000,000 MW.

Sources. These ingredients are generally not locally available. See Sources (Ingredients) for a list of web sites from which these ingredients are available. Note that J-Lube is sometimes available from veterinary supply stores that cater to livestock as it is used in birthing large animals.

NMEC[]

Edward has been working with the notion of NMEC (nominal minimum effective concentration). This is the minimum amount of the polymer required to activate a water and Dawn Pro solution (in the proportion of 20 parts water to 1 part Dawn Pro) so that with a small plastic wand one can blow 5 bubbles per dip. Amounts less than the NMEC have a detectible influence, but this was chosen as the low end of the effective range. Based on reports from Edward and a few others, the NMEC for fresh WSR301 is around 0.008 grams per liter water (0.03 grams PEO per gallon water).

See PEO Calibration for a method of estimating the NMEC of your PEO. Information about using NMEC to adjust recipes is found here.

Provisional NMEC estimates (March 2015)

| Polymer | NMEC (grams per liter water) | Useful Range | Notes |

|---|---|---|---|

| PolyOx WSR301 |

0.008 grams/liter (0.03 grams/gallon) 0.0008% !!!! (not a typo) |

Based on a batch received from Teacher's Source receive April 2014 and stored in freezer. Tests performed May 2014. Tests of fresh sample from Dow would be helpful. Influence detectible at even lower levels. |

eGoo uses 5-8.5 times the NMEC Bubble Power Powder uses about 8.5 times the NMEC |

| J-Lube | 0.032 grams/liter (0.12 grams/gallon) | Based on report from Wiki member Jan. 2015 |

NOTE: If these NMEC numbers are correct for full-potency, PEO, 0.8 grams of a 1% PEO solution should activate about a liter of 20:1 water:Dawn Pro to a minimally effective bubble juice. And 10 times that much should be tolerated. The upper bound needs exploration.

If you can establish the NMEC upon which a recipe is based and the NMEC of your particular PEO batch, you can adapt the amount you use to account for differences in potency. As of March 2015, the amounts are provisional but seem effective. We hope hear back from Wiki visitors so that we can refine the estimates.

Using the NMEC. Most recipes use several times the NMEC. eGoo, for instance, uses 5-8.5 times the NMEC -- even more can PEO can be used but the juice may become quite stringy. Bubble Power Powder uses about 8.5 times the NMEC.

Stringiness[]

PEO, especially full-potency high molecular-weight PEO like WSR301 or J-Lube introduces a 'stringy' quality. Near the NMEC (see above), the stringiness is pretty minimal and may not be noticed. At 10 times the NMEC, the stringiness is quite pronounced.

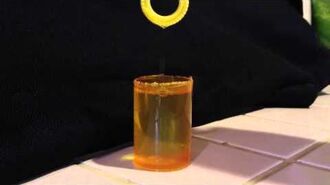

PEO Stringiness Demo

The video gives you an idea of what to look for. A mix can be stringier than the 'just right' solution shown in the video.

2012 08 Old and Fresh Jlube eGoo Comparison

Comparison of UNDILUTED eGoo concentrate made with same amount of PEO from two batches whose potency is significantly different due to degradation. If your eGoo is as stringy as the concentrate on the right, you need to use less PEO!

This video demonstrates the extreme difference between degraded and undegraded PEO. Both mixes were mixed using identical methods and water sources and the same amounts of two different batches of J-Lube (one a few years old and the other a new batch that had been stored in the freezer. This is undiluted eGoo concentrate. So, you won't see stringiness like this in the finished juice. If your concentrate is as stringy as the one on the right, reduce the amount of PEO significantly. The one on the right has 4 times too much!

The stringiness by itself can be confusing because degraded PEO (which MANY bubblers prefer) creates a less stringy bubble juice than undegraded PEO EVEN WHEN THE AMOUNT IS ADJUSTED to account for the degradation.

Usage Notes[]

The amount of WSR301 or J-Lube used in bubble recipes can vary quite a bit. A review of recipes on the wiki suggests to me that the amounts in some recipes here and elsewhere on the web are based on somewhat degraded PEO rather than full-potency PEO -- as the amounts used are sometimes so high that with full-potency PEO, it is hard to imagine the bubbles working.

The amount to use listed for J-Lube and WSR301 is a conservative estimate. An even wider range may be effective, though we think that the optimal useful amount probably falls in this range for most mixes.

Usage range below is based on full-potency PEO. You may need to use as much as 4 or 5 times more than this if your PEO has degraded.

EDITOR'S NOTE: Refine ranges based on full-potency PEO. What is the overdose point? Where is it really barely taking effect? Provide a simpe method of judging potency.

Use in concentrates. PEO works very nicely in concentrates. As with most of the polymers that we use, there is not enough water in Dawn/Fairy family detergents (at least the normal high-concentration versions) to keep the PEO to keep WSR301 or J-Lube in suspension without some additional water.

MEASURING BY WEIGHT OR VOLUME! While we provide some suggestions about volumetric measures, we strongly suggesting measuring either J-Lube or WSR301 by weight with a good scale rather than by volume if you want consistent results. Volumetric measurements vary in the corresponding weight by enough a factor that it can significantly impact your juice. With J-Lube, for instance, the weight of the amount packed into 1/8 teaspoon can vary by as much as 20% from instance to instance no matter how much care you take.

J-Lube[]

Amount to use per U.S. gallon of water (3785.4 ml). 0.4 - 1.3 grams per gallon of water. Or about 1/8 packed tsp to 1/2 packed tsp. Egoo uses about 1 gram per gallon of water (about 3/8 packed teaspoon).

Amount to use per liter of water water (1000 ml). 0.1 grams - 0.36 grams per liter of water. Or about 1/16 packed tsp to 1/8 packed tsp. Egoo uses about 0.26 grams per liter of water.

Weight by volume. 1/8 tsp. (.616ml) packed J-Lube weighs approximately 0.25-0.42 grams (0.35 has been the average). Measurement by weight is recommended as a small difference in weight can be significant.

PolyOx WSR301[]

Amount to use per U.S. gallon of water (3785.4 ml). 0.1 - 0.35 grams WSR301 per gallon of water. Egoo makes use of about 0.25 grams per gallon.

Amount to use per liter of water water (1000 ml). 0.0264 grams - 0.092 grams (0.1 grams?) WSR301 per liter of water. Egoo makes use of about 0.066 grams per liter.

Weight by volume. 1/8 tsp. packed = approx 0.3 grams -- amount of variance not known due to limited experience. WSR301 is so potent that we highly recommend measuring by weight. Even a small difference in amount can lead to huge differences in stringiness and performance.